- Polyurethane screens

- Polyurethane fine screen panels

- Polyurethane coated wire screens

- Dewatering screen panels

- Flip flow screen panels

- Rubber screens

- Woven wire screens

- Self cleaning screens

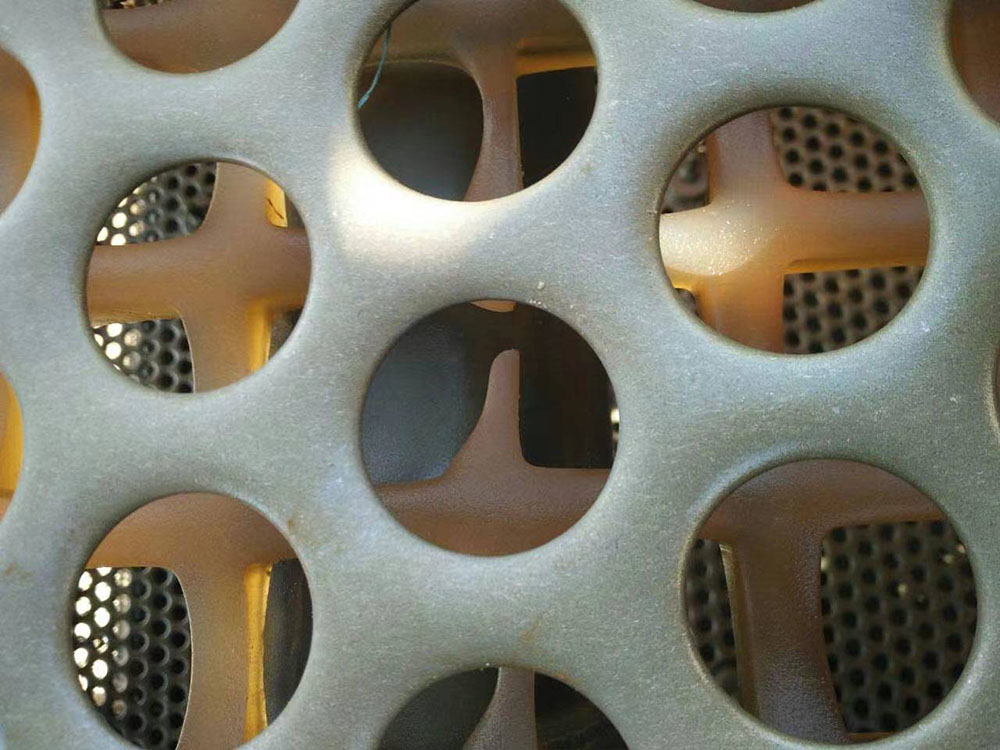

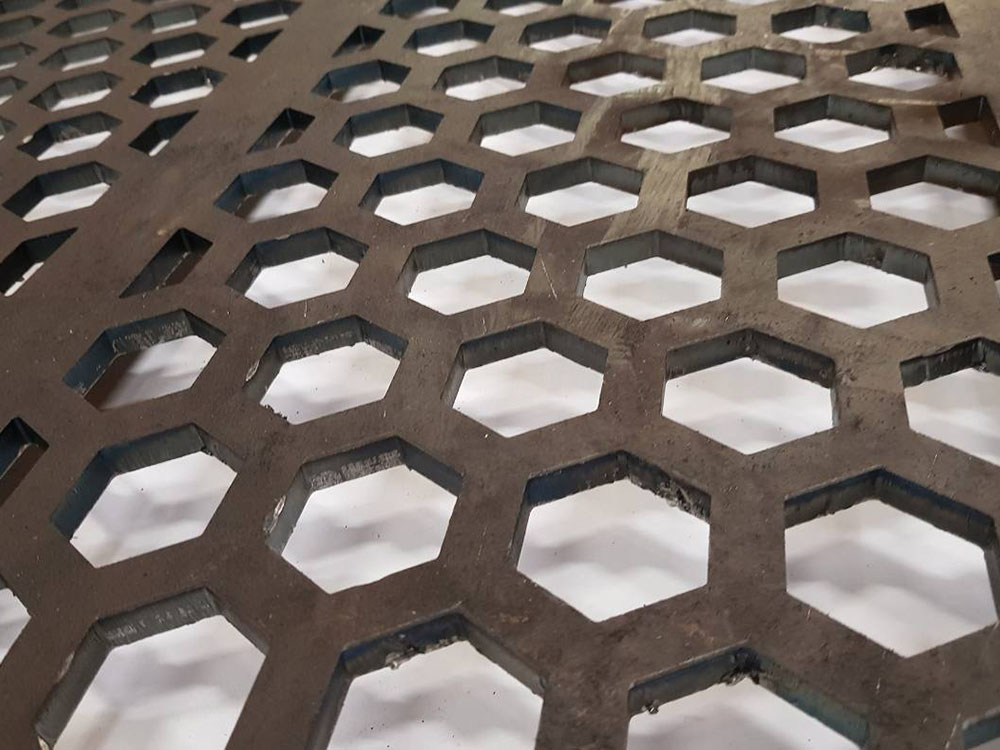

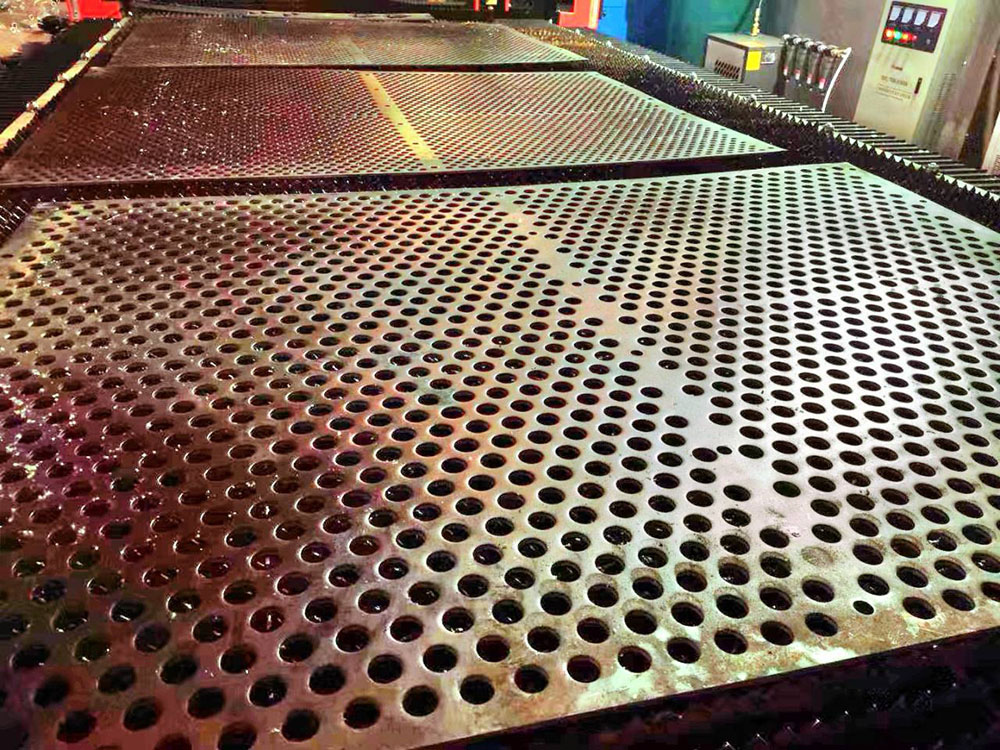

- Perforated plate screens

- Screening accessories

- Polyurethane sheets and lined pipes

- Polyurethane rollers and tires

- Rubber wear liners and rubber lined pipes

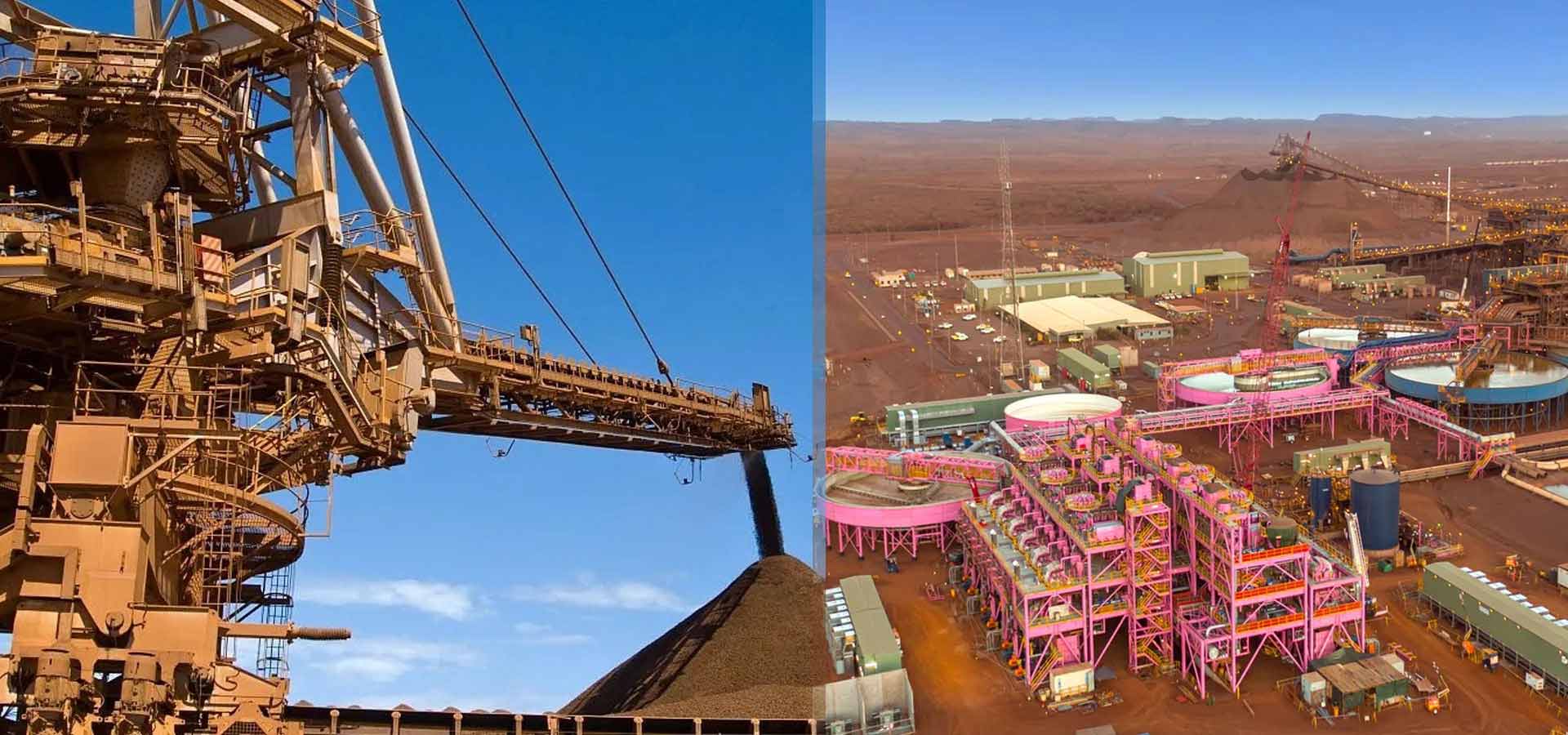

- Conveyor belts and conveyor pulley

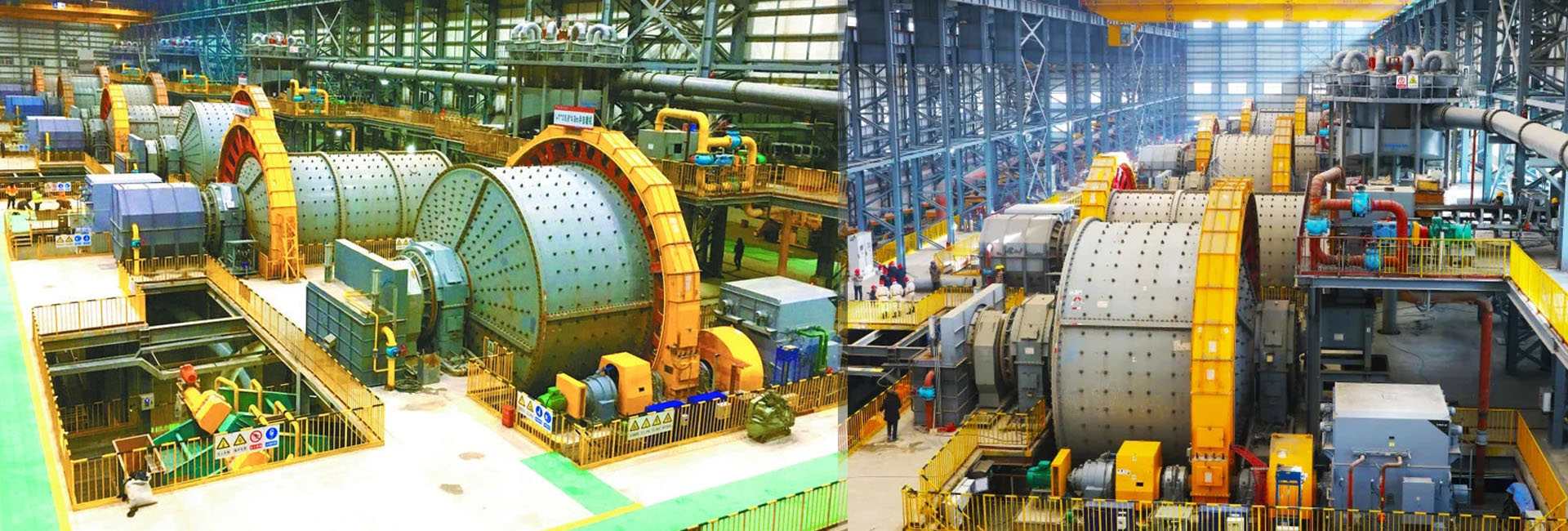

- Vibrating screens and filter press

- Hydrocyclone

- Crusher wear parts and backing compound

- Flocculant

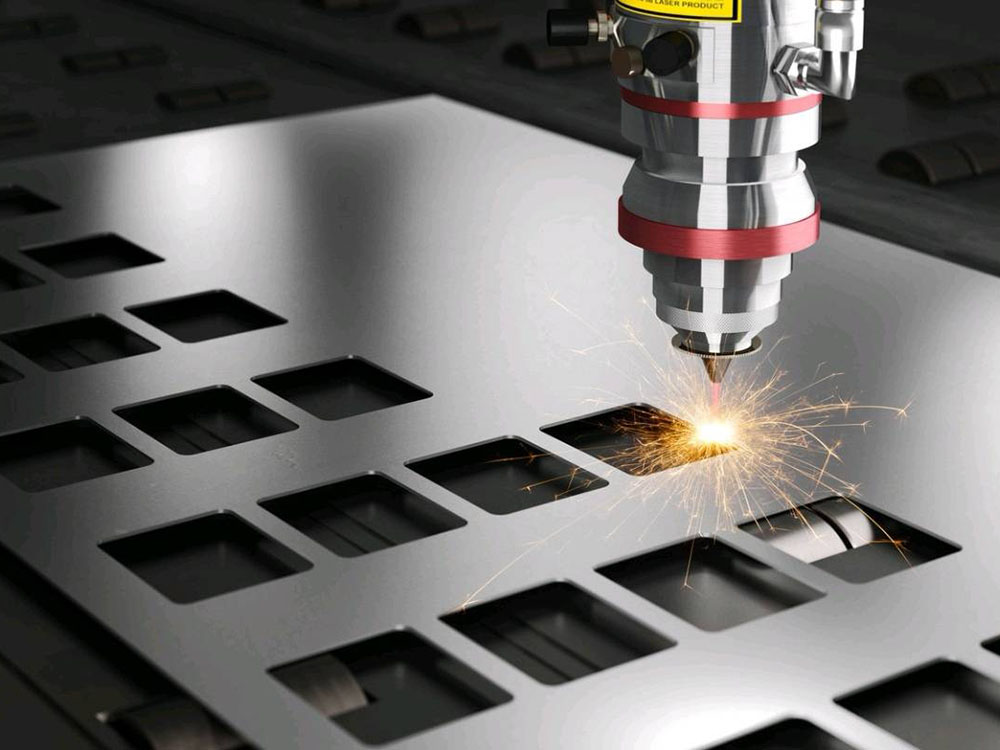

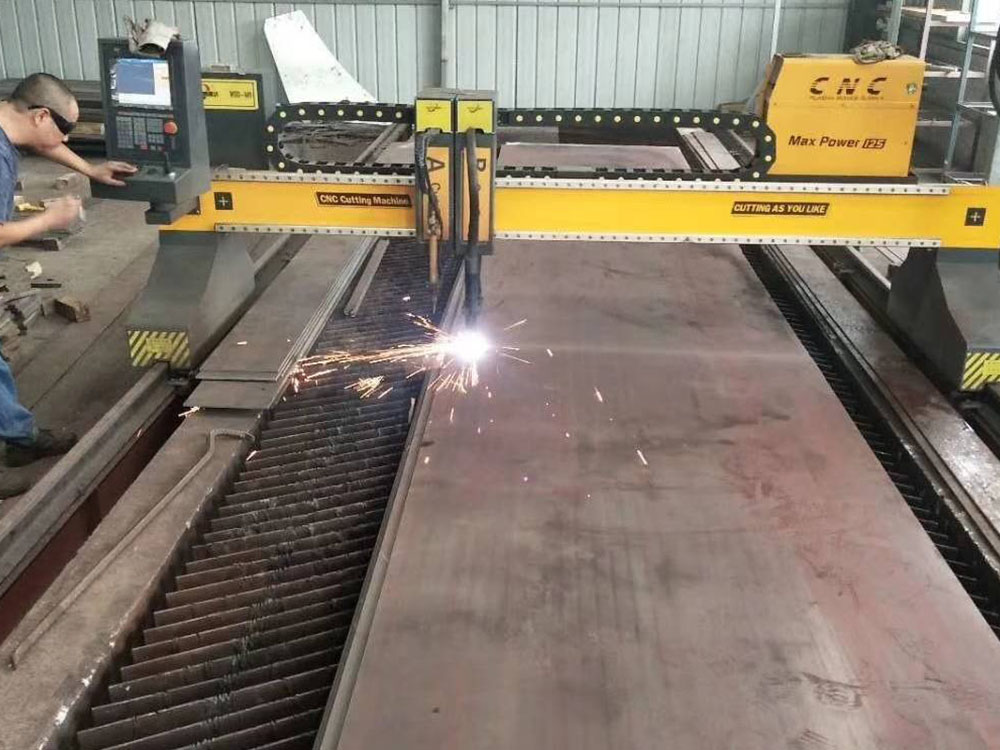

Flame-cutting screens

Flame-cutting screens

Details:

Specifications

- Screen size

- Customize

- Thickness

- 1 - 20mm

- Opening size

- 1 - 350mm

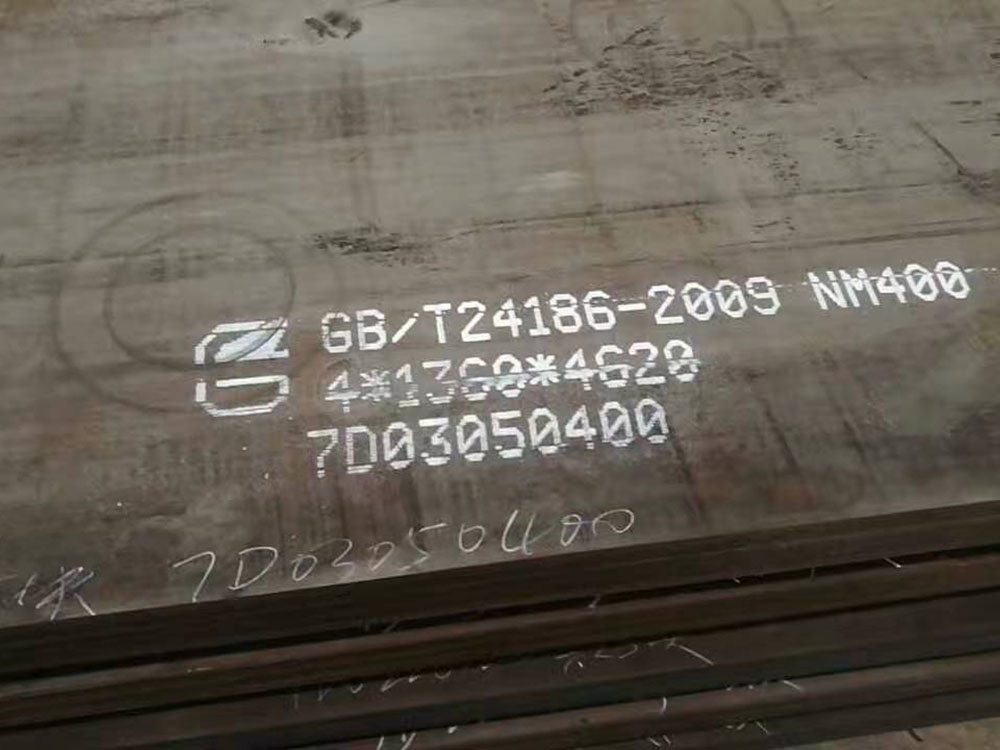

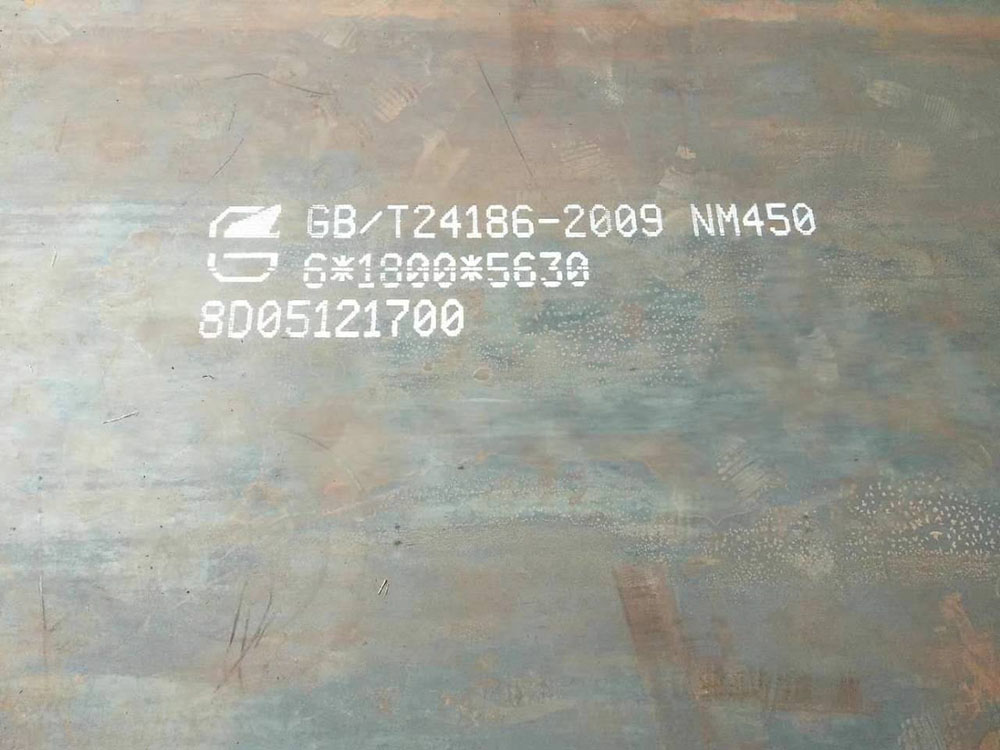

This quench and tempered (heat treated) material screen has been an industry lead player for many years. While the heat-treating process adds more expense to the product, it also allows the plate to last a long time in very abrasive environments such as crushed granite and granite-based sand and gravel.

Flame-cut plate screens feature square, round, hexagonal, and slotted openings that are cut into steel plate, rather than perforation. This design is excellent for top and sometimes middle-deck applications where impact and abrasion resistances are required. We offer flame-cut plate screens with BHN hardness of up to 450 or 550 for superior wear life.

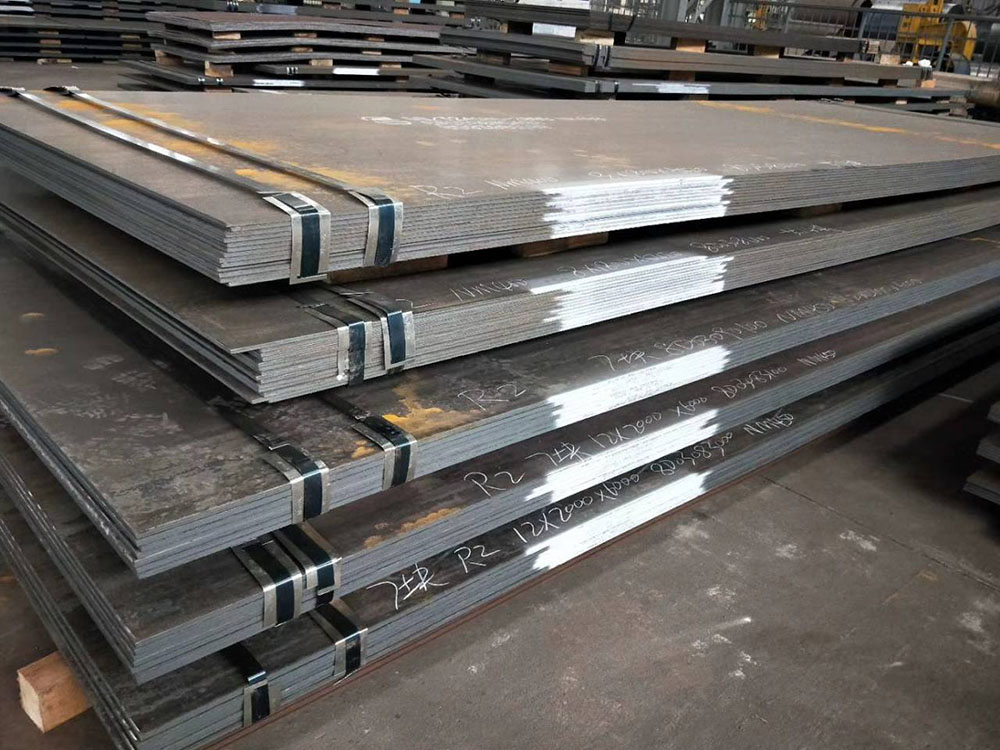

Material Used:

Heat treated NM400、NM450、NM500、NM550 wear resistance steel plate