- Polyurethane screens

- Polyurethane fine screen panels

- Polyurethane coated wire screens

- Dewatering screen panels

- Flip flow screen panels

- Rubber screens

- Woven wire screens

- Self cleaning screens

- Perforated plate screens

- Screening accessories

- Polyurethane sheets and lined pipes

- Polyurethane rollers and tires

- Rubber wear liners and rubber lined pipes

- Conveyor belts and conveyor pulley

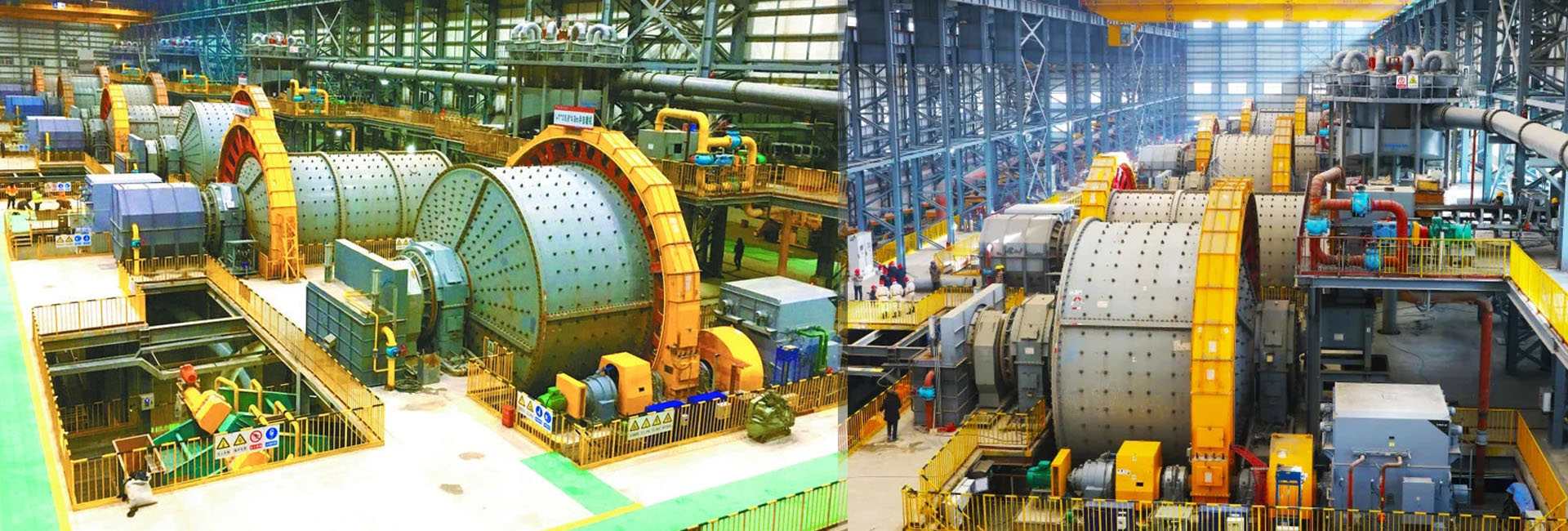

- Vibrating screens and filter press

- Hydrocyclone

- Crusher wear parts and backing compound

- Flocculant

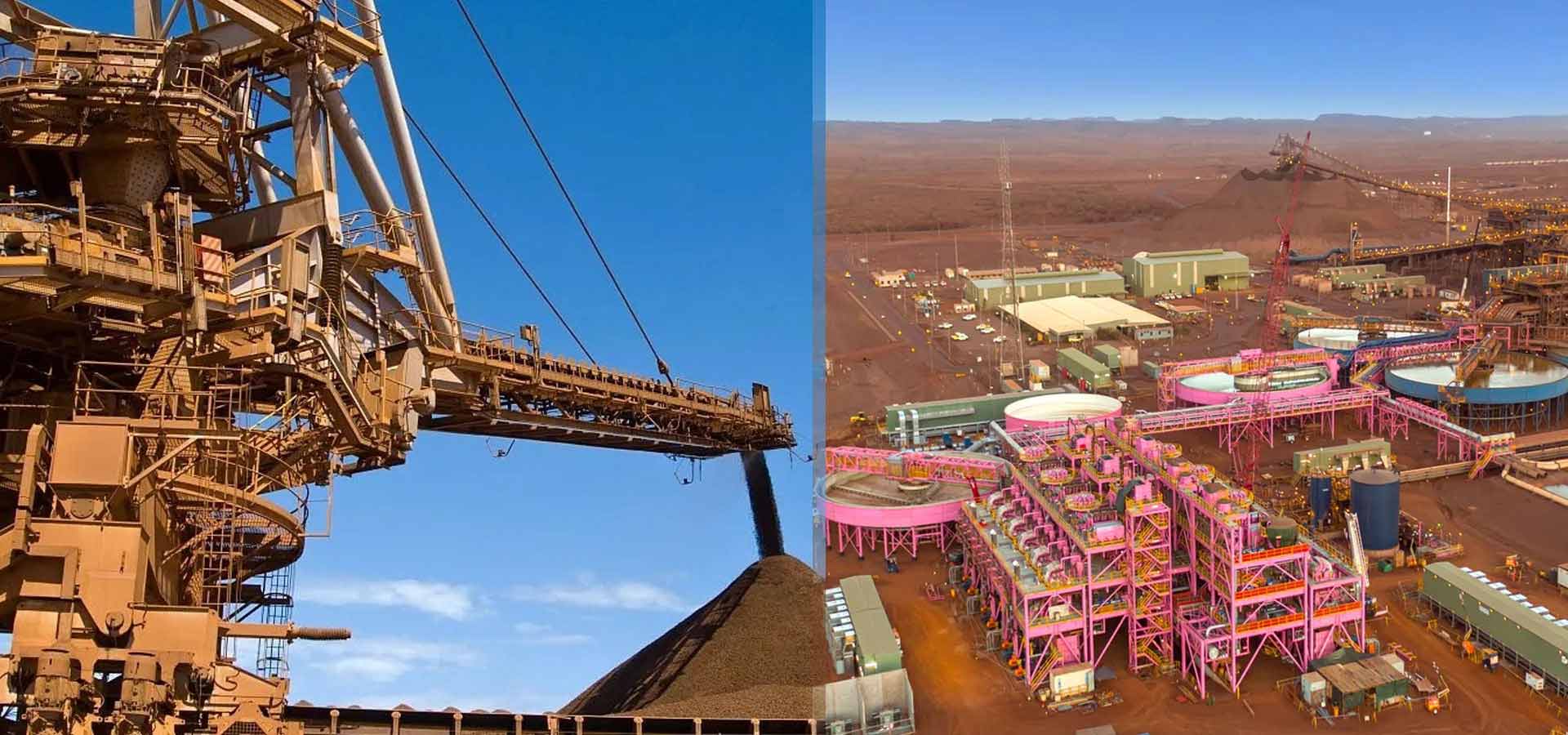

Haul truck rubber liners and crusher rubber liners

Haul truck rubber liners and crusher rubber liners

Whether moving material from the pit to the crushers or overburden to dump sites, Haul Trucks have to face extreme impact conditions when the shovel discharges the load on the Box.

Consult now

Details:

-

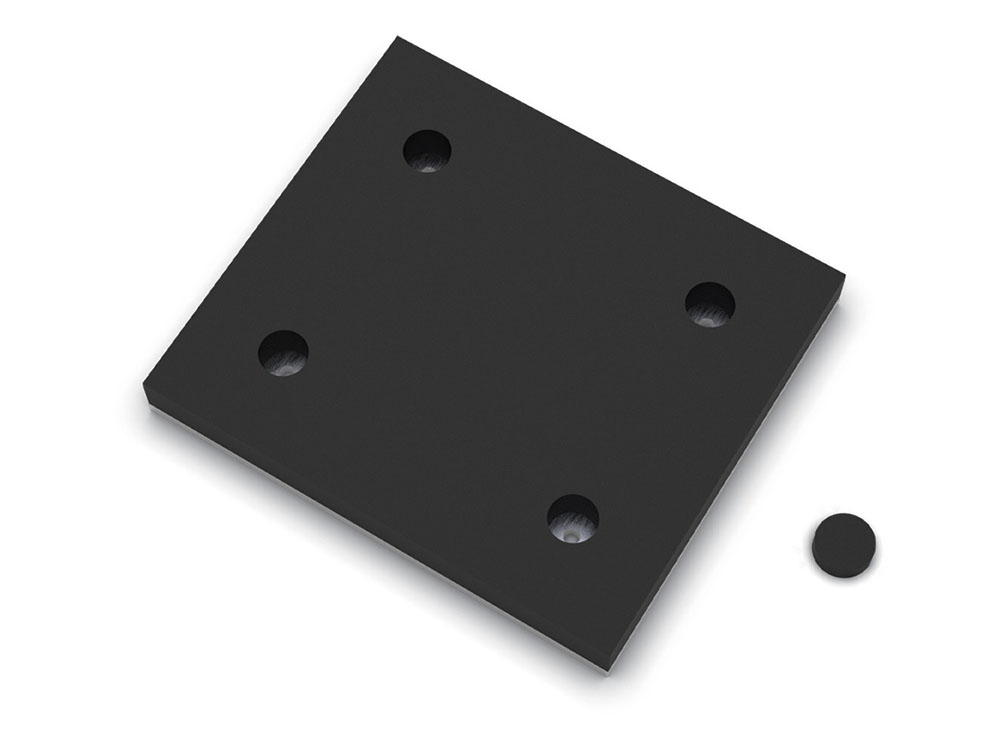

Specifications

- Size

- Customize

- Thickness

- 1 - 300mm

- Hardness

- 40 - 90A

The rubber compounds developed for this application employ top quality raw materials which yield an excellent compound engineered exclusively for this application. These compounds offer high tensile strength, superior impact and abrasion-resistant characteristics, outstanding chunking resistance and superior bonding to steel. Mixed in our own factory to exacting specifications, and pressure molded to various substrates, these compounds offer the highest wear performance available in the market

Truck beds lined with our Rubber Haul Truck Bed liners have proved to be very long lasting, maintenance free, and most importantly, the cost/benefit ratio is excellent. We have extensive experience designing and manufacturing Rubber Bed Liners for both Haul Trucks and Articulated Trucks.Lower cost-per-processed ton in comparison to alternative rubber liners, and high brinell steel wear platesSuperior wear life due to advanced rubber compounds compared to alternative linersReduced structural damage of box and chassis maximizes life of the truck itself

Lower noise levels and vibration, and reduced load shock-80% reduction of noise in the cab and 85% reduction at a 50-foot distance; driver fatigue is greatly reducedLower carry back of wet, sticky ore