Classify

- Polyurethane screens

- Polyurethane fine screen panels

- Polyurethane coated wire screens

- Dewatering screen panels

- Flip flow screen panels

- Rubber screens

- Woven wire screens

- Self cleaning screens

- Perforated plate screens

- Screening accessories

- Polyurethane sheets and lined pipes

- Polyurethane rollers and tires

- Rubber wear liners and rubber lined pipes

- Conveyor belts and conveyor pulley

- Vibrating screens and filter press

- Hydrocyclone

- Crusher wear parts and backing compound

- Flocculant

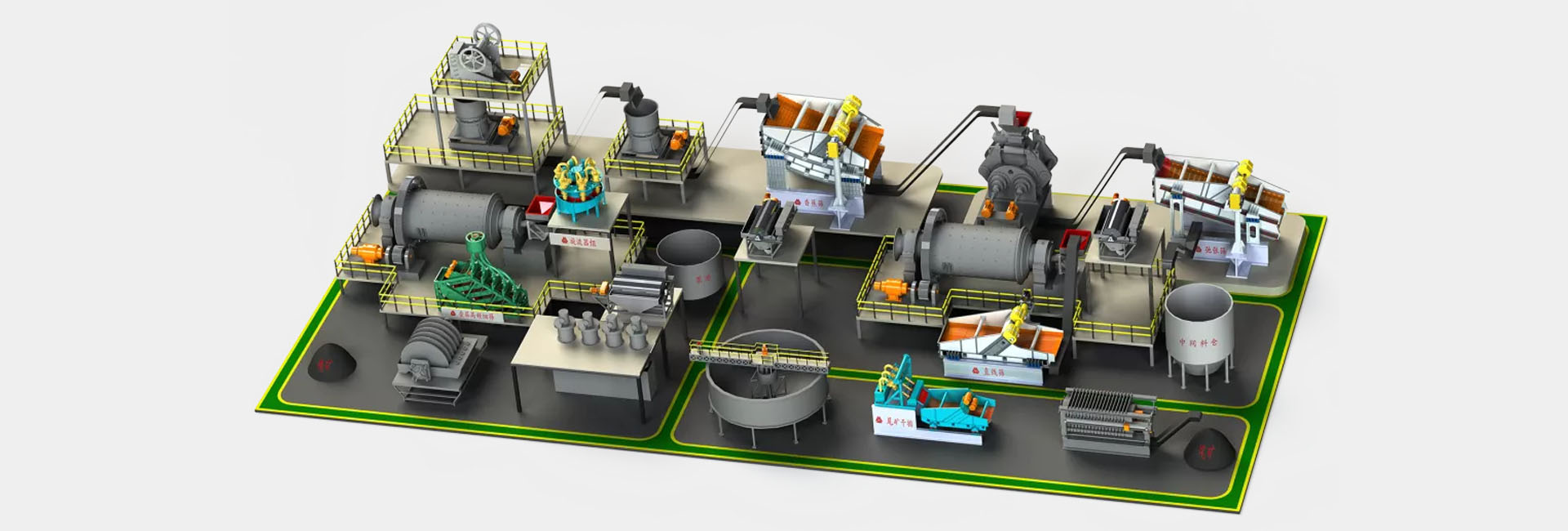

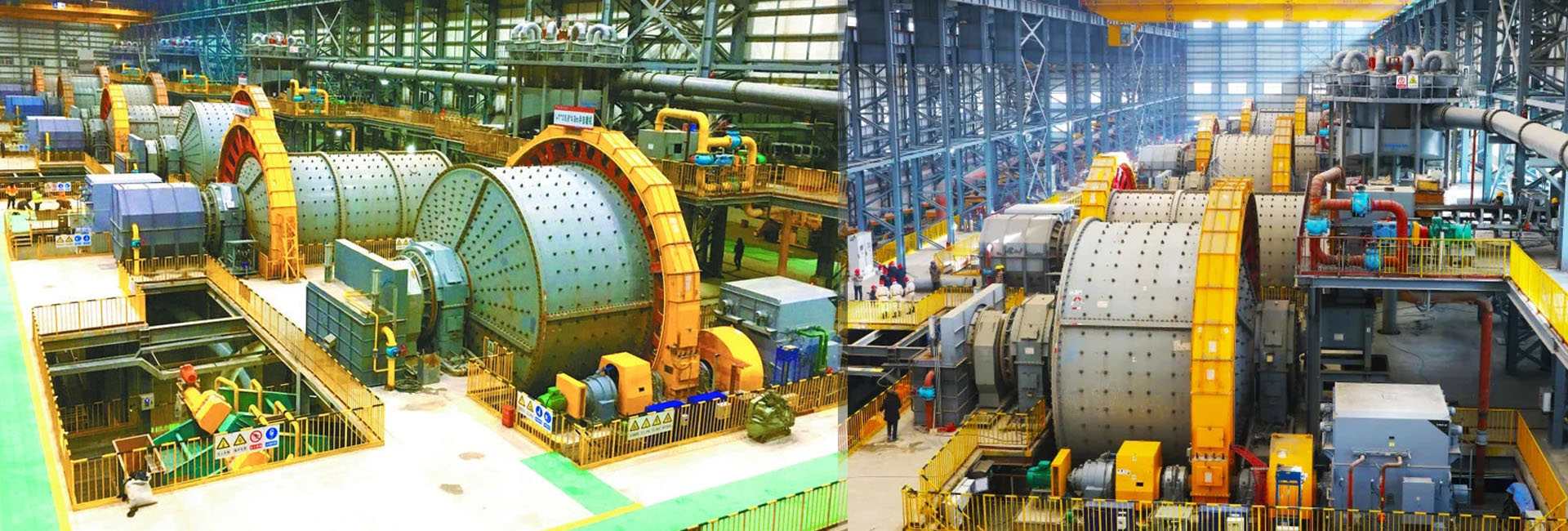

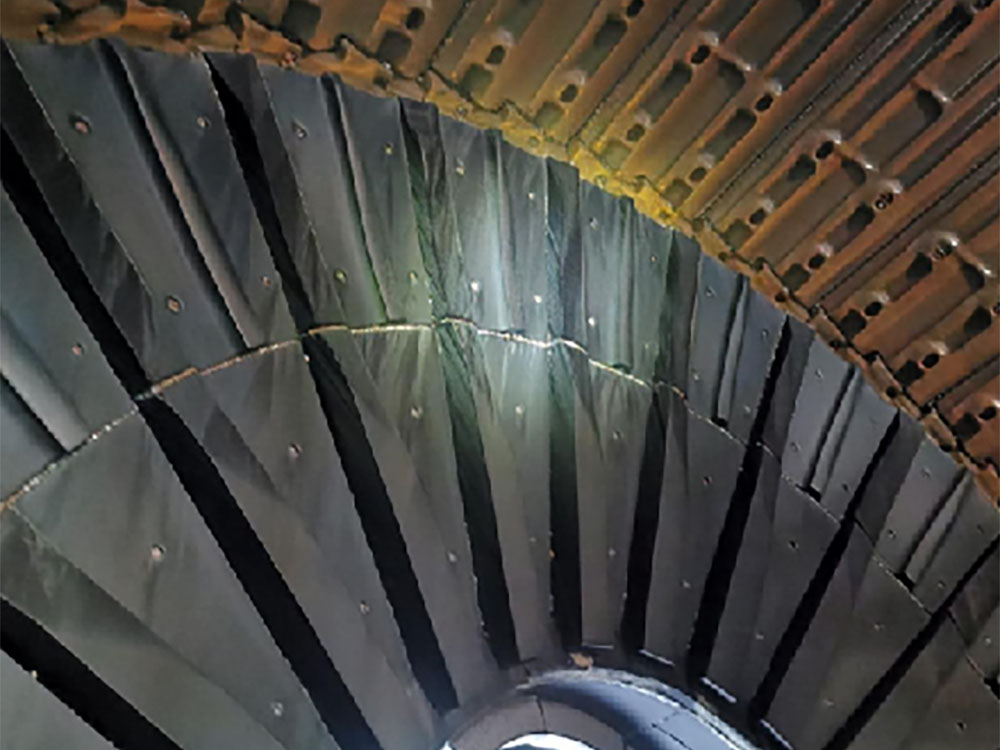

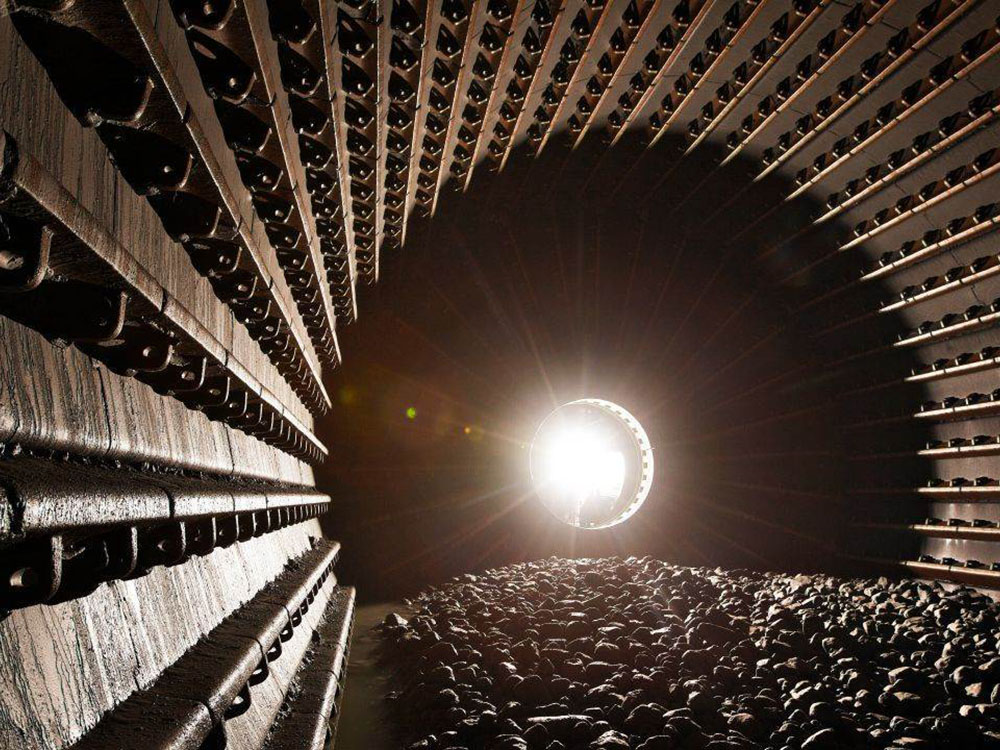

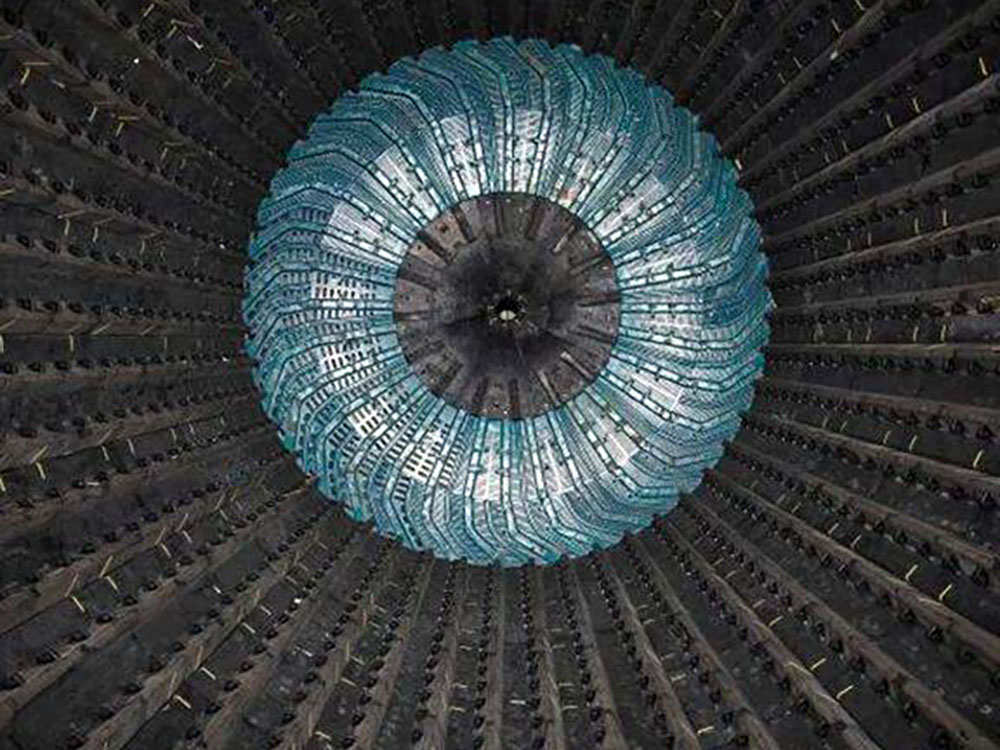

Mill rubber liners

Mill rubber liners

Rubber mill liners from Seiko extend the lifespan of your mineral processing equipment by protecting the inner shell from impacts and abrasions caused by processing different types of minerals. Seiko, a leader in wear solutions, has developed optimised rubber mill liner designs that result in less wear than standard liners.

Consult now

Details:

-

Specifications

- Size

- Customize

- Thickness

- 3 - 300mm

- Hardness

- 40 - 90A

Product features:

Greater wear resistance extends the lifespan of your equipment

Quick to install and replace, reducing downtime

Their low weight results in less wear on bearings and reduced energy requirements