- Polyurethane screens

- Polyurethane fine screen panels

- Polyurethane coated wire screens

- Dewatering screen panels

- Flip flow screen panels

- Rubber screens

- Woven wire screens

- Self cleaning screens

- Perforated plate screens

- Screening accessories

- Polyurethane sheets and lined pipes

- Polyurethane rollers and tires

- Rubber wear liners and rubber lined pipes

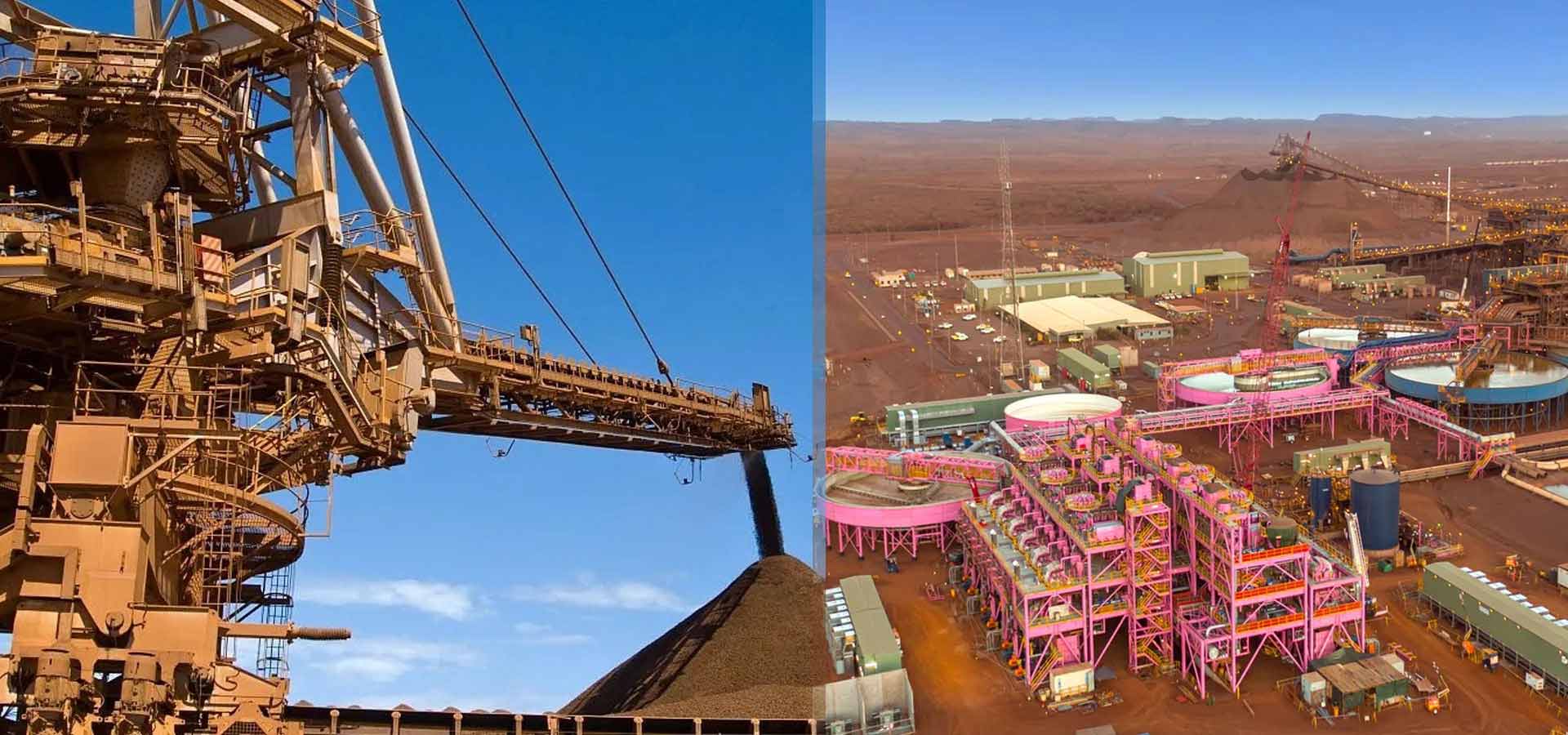

- Conveyor belts and conveyor pulley

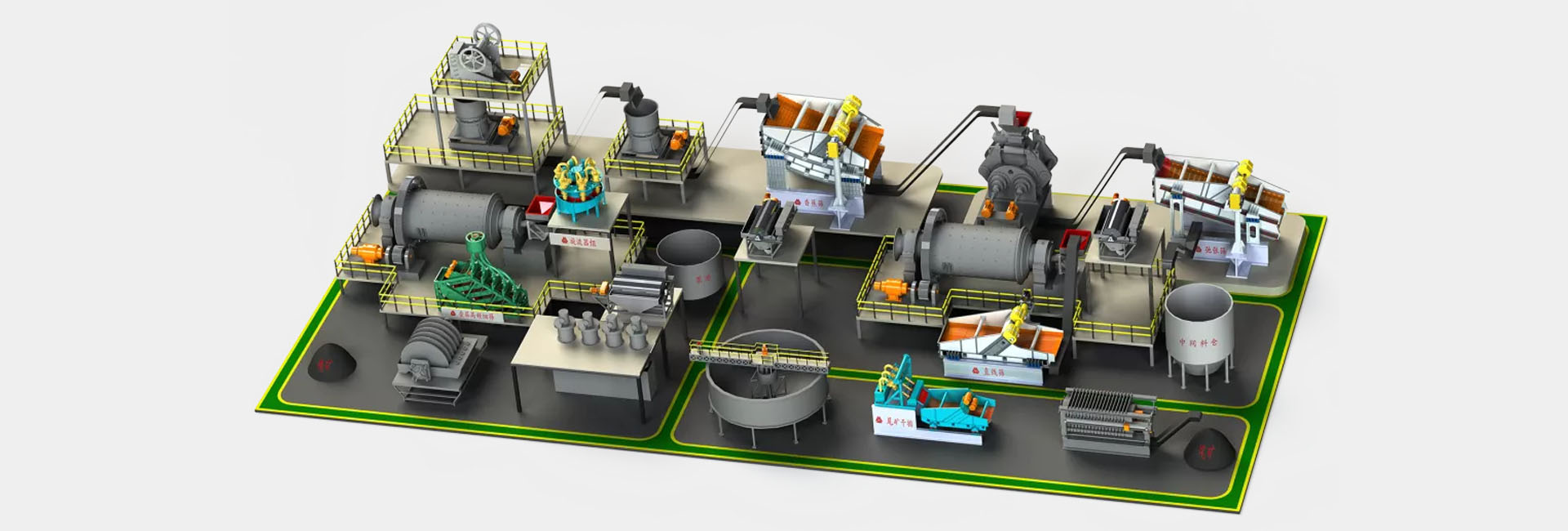

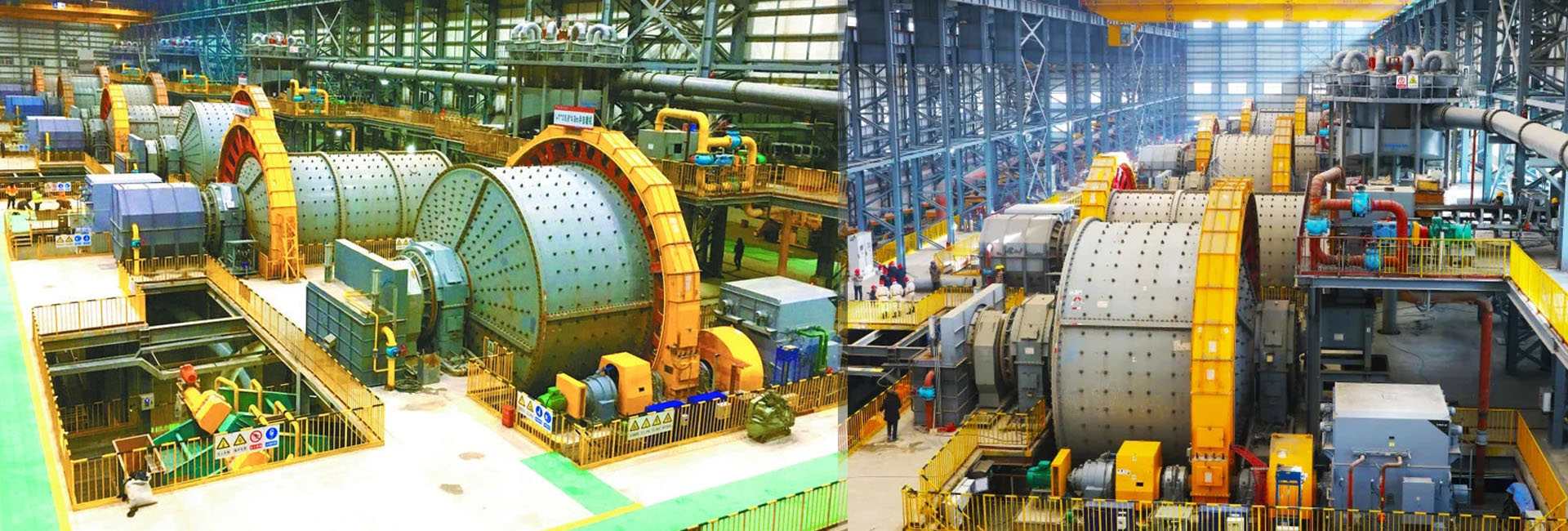

- Vibrating screens and filter press

- Hydrocyclone

- Crusher wear parts and backing compound

- Flocculant

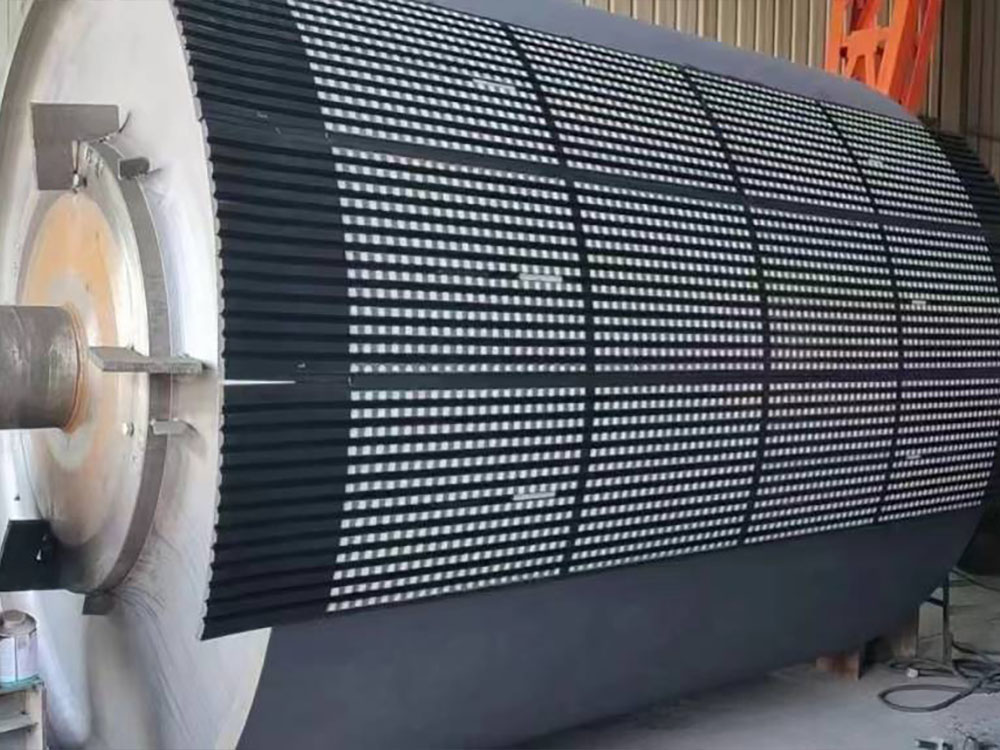

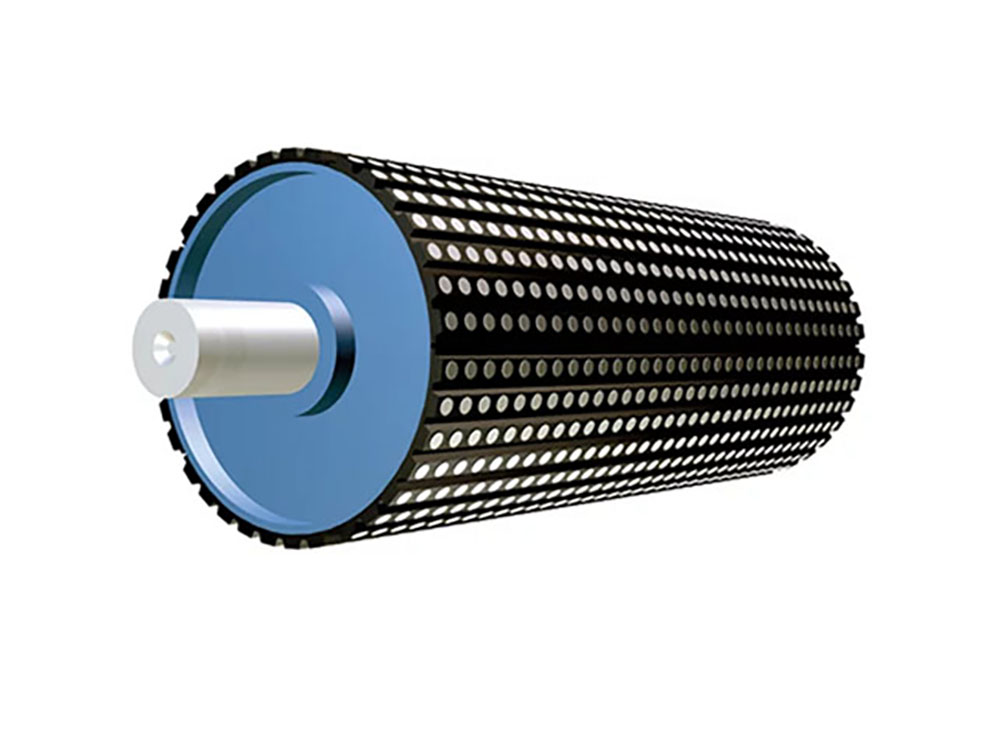

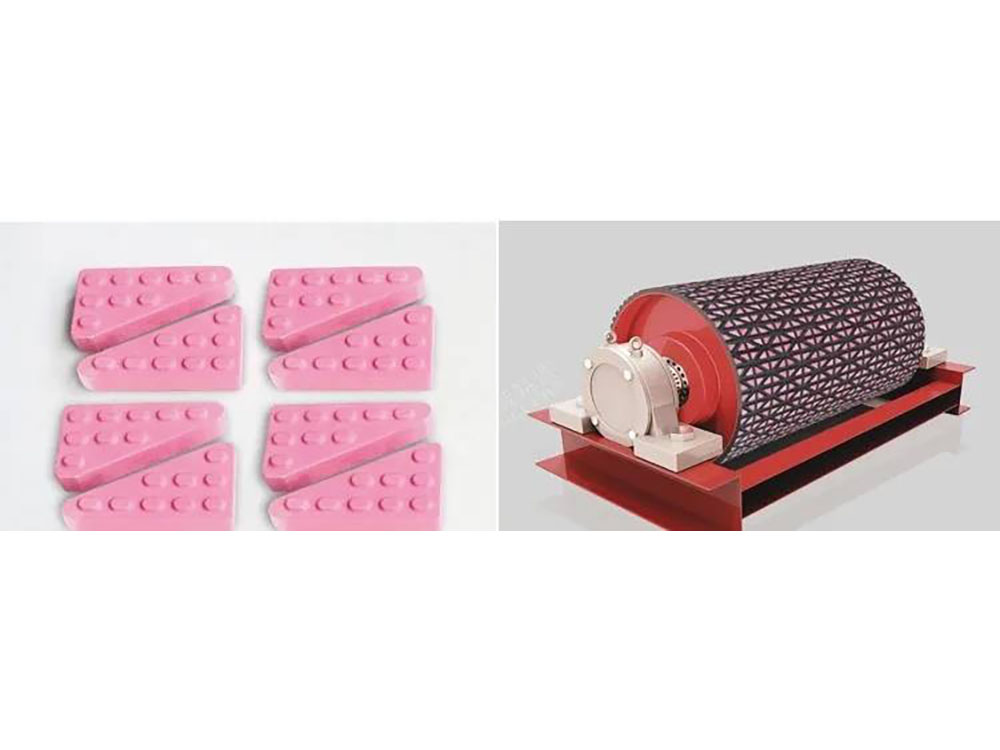

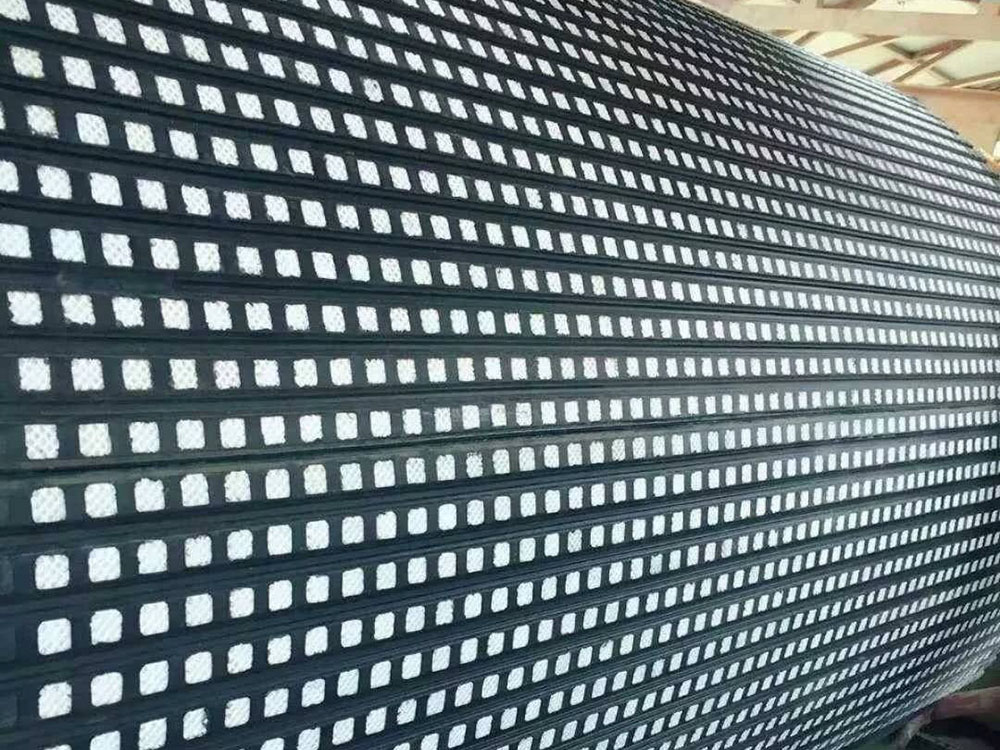

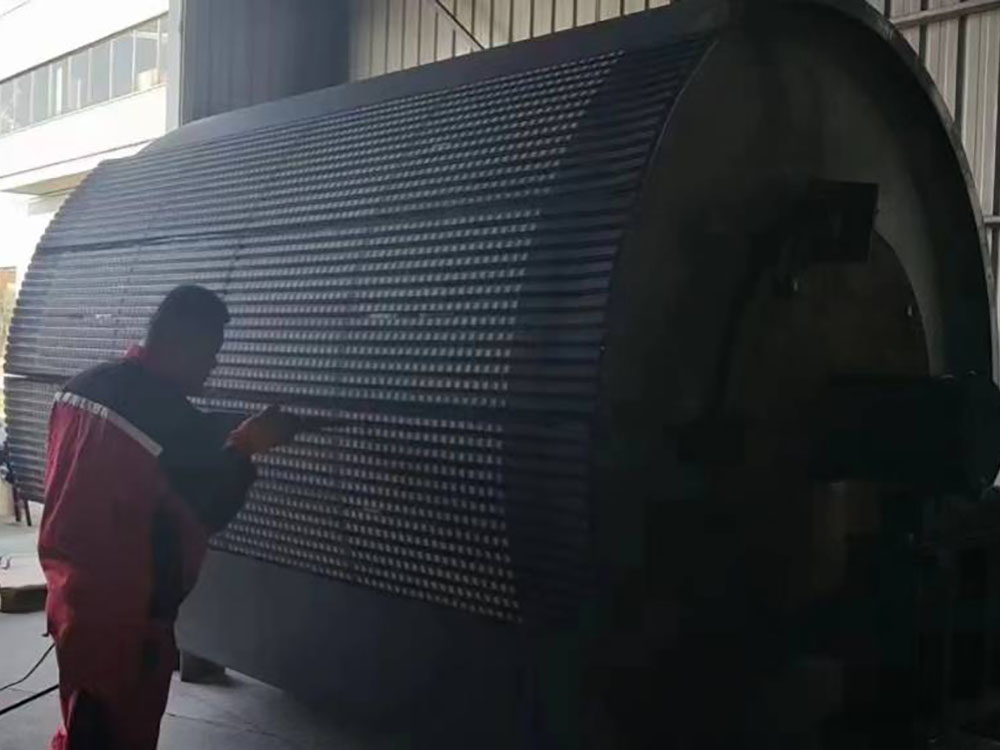

Ceramic coated conveyor pulley

Ceramic coated conveyor pulley

Ceramic pulley lagging provides the solution when conventional rubber lagging fails to correct belt slippage and wears prematurely. Our unique ceramic is designed for the highest drive factors unlike the conventional square tiles.

Consult now

Details:

-

Specifications

- Size (D)

- 500-2000mm or customize

- Hardness

- 65- 90A

Increase Productivity – by delivering increased traction between the conveyor belt and pulley, allows for lower belt tension than with rubber lagging.

Bonding Strength – that is superior to others, due to 3mm of our neoprene compound vulcanized into the bottom-side of the lagging.

Superior Wear – ability in abrasive or highly wet or dry applications as seen in below ground and above ground mining.