Classify

- Polyurethane screens

- Polyurethane fine screen panels

- Polyurethane coated wire screens

- Dewatering screen panels

- Flip flow screen panels

- Rubber screens

- Woven wire screens

- Self cleaning screens

- Perforated plate screens

- Screening accessories

- Polyurethane sheets and lined pipes

- Polyurethane rollers and tires

- Rubber wear liners and rubber lined pipes

- Conveyor belts and conveyor pulley

- Vibrating screens and filter press

- Hydrocyclone

- Crusher wear parts and backing compound

- Flocculant

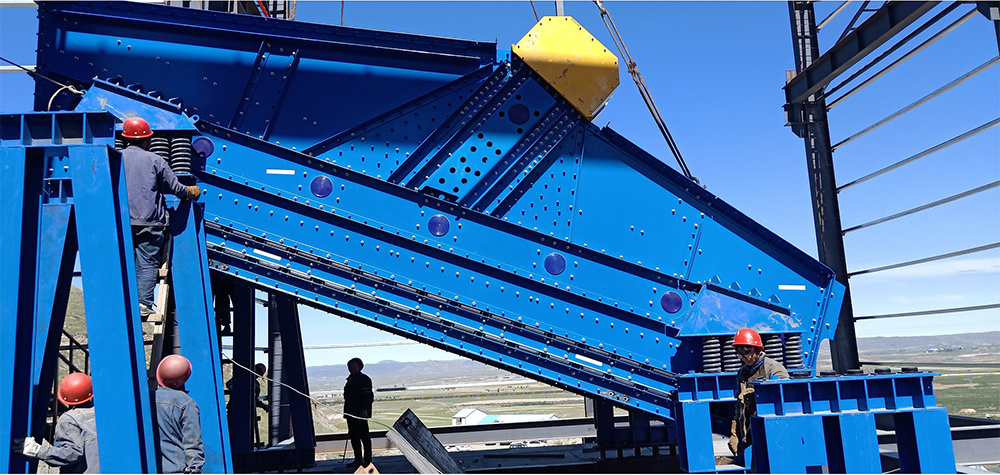

Flip flow vibrating screens

Flip flow vibrating screens

Screening challenging and inhomogeneous products requires special processing technology. During operation, blockages in the screen are almost entirely prevented and the material is dispersed to enable fine grain separation.

Consult now

Details:

-

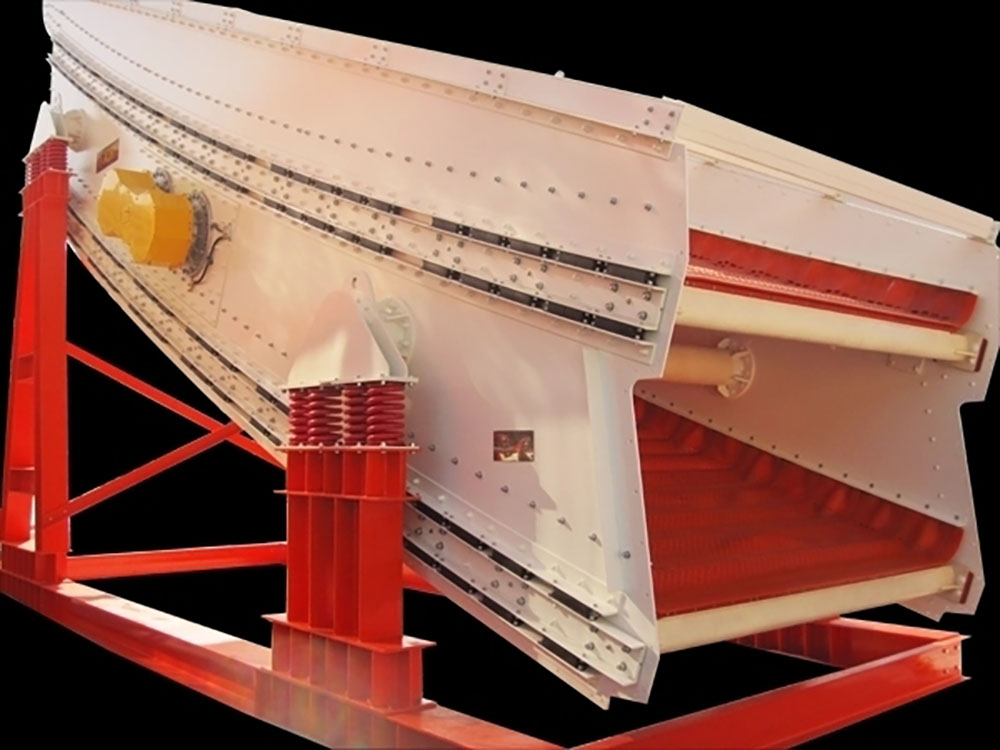

Specifications

- Size ( W & L )

- 1860-43120 or customize

- Capacity ( t/h )

- 150-1500

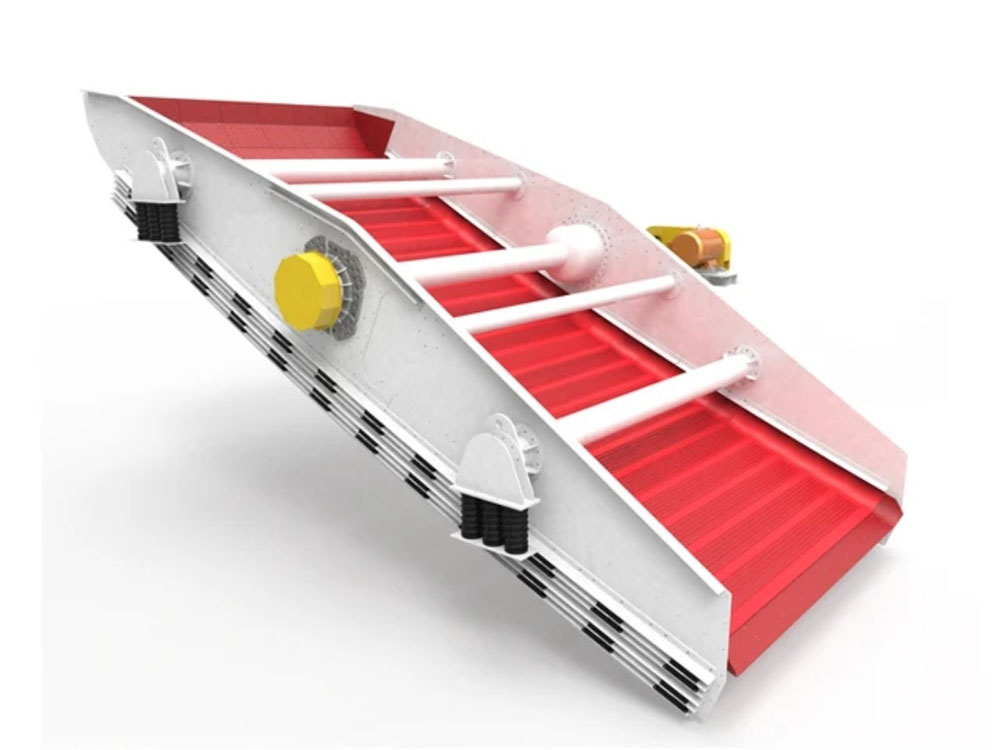

Flip-Flow Screens is based on a resonance system. The internal screen frame performs a relative motion in reaction to the directly excited external frame. Flexible polyurethane screens are attached to both frames with one side each. The relative motion of the frames exerts and releases tension on the screens, resulting in acceleration rates of up to 50 G on the screen deck.

Some typical applications

Iron Ore at 6mm with 15% moisture

· Raw sand at 3mm with 6% moisture

· Compost at 10mm with 50% moisture

· Slag at 3mm with 10% moisture

· Salt at 3 mm with 5 % moisture

· Coke at 3mm with 20% moisture

· Lignite at 6mm with 50% moisture

· Coal at 6mm with 18% moisture

· Limestone at 3mm with 20% moisture · Pet coke at 3mm with 18% moisture