Classify

- Polyurethane screens

- Polyurethane fine screen panels

- Polyurethane coated wire screens

- Dewatering screen panels

- Flip flow screen panels

- Rubber screens

- Woven wire screens

- Self cleaning screens

- Perforated plate screens

- Screening accessories

- Polyurethane sheets and lined pipes

- Polyurethane rollers and tires

- Rubber wear liners and rubber lined pipes

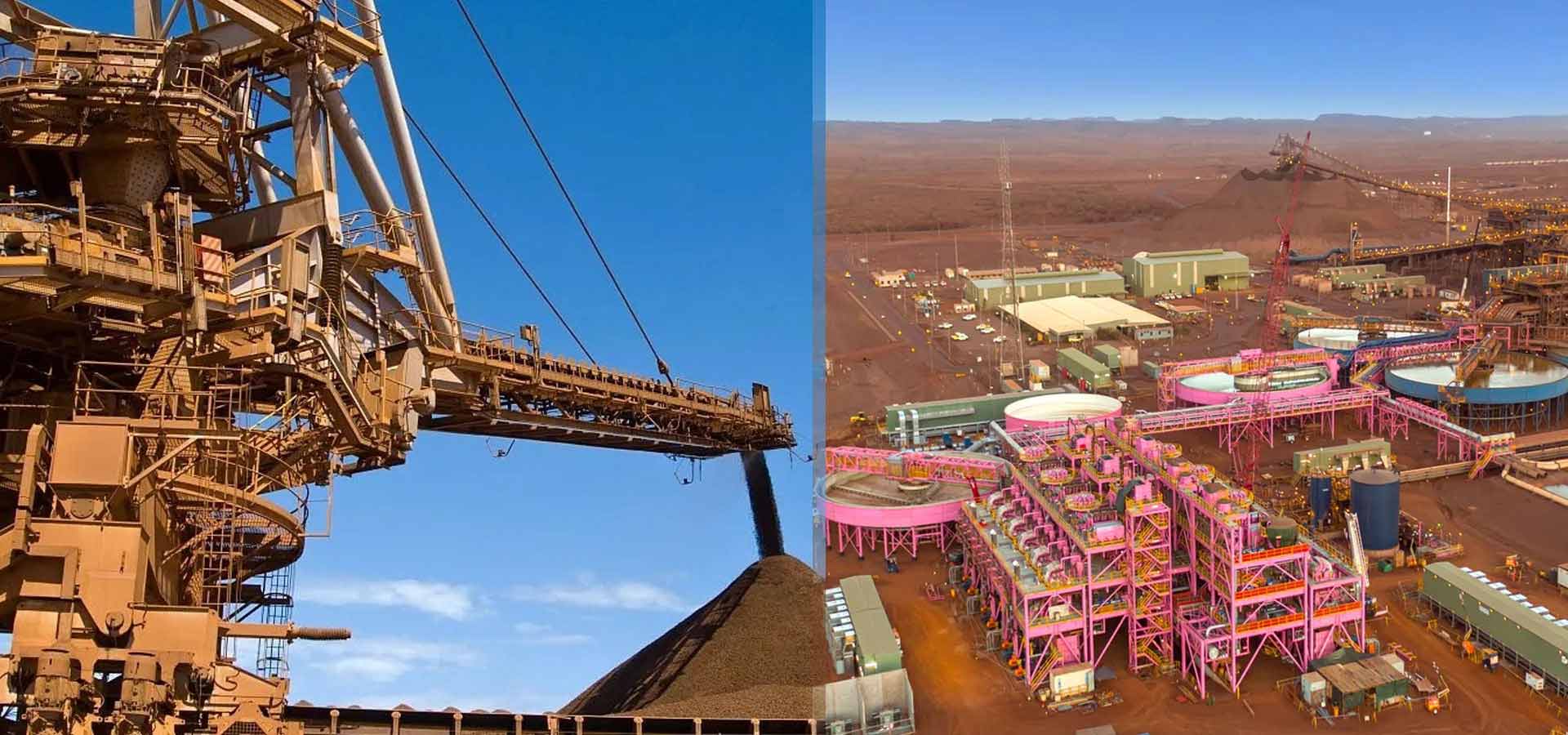

- Conveyor belts and conveyor pulley

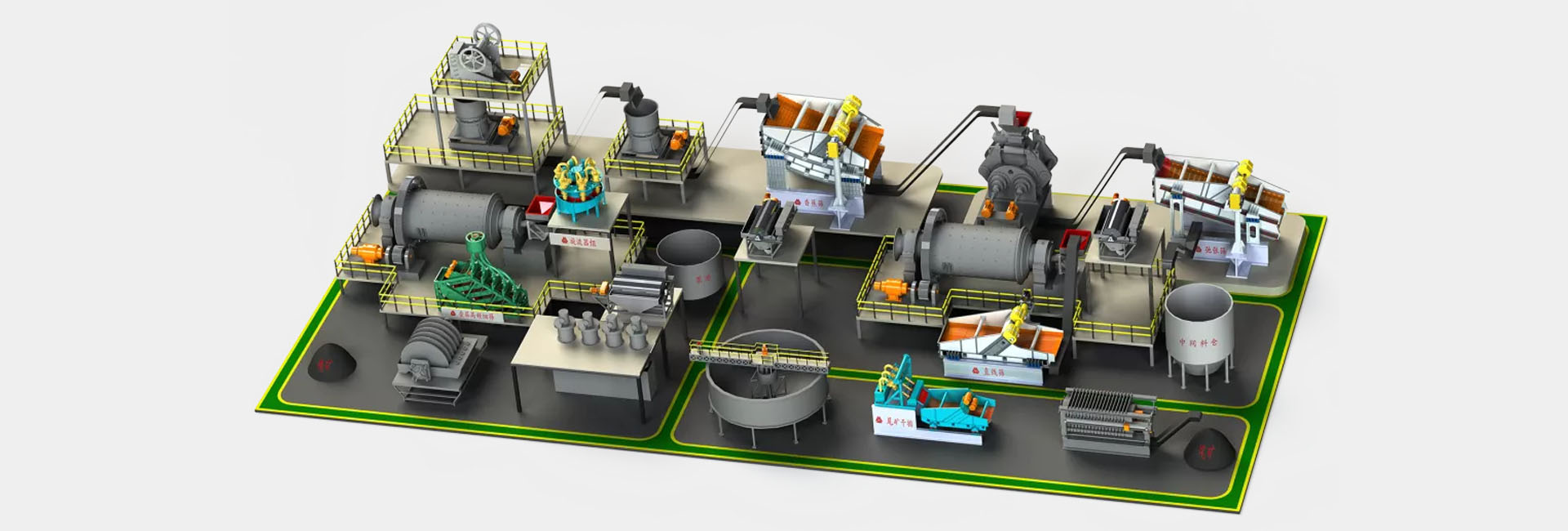

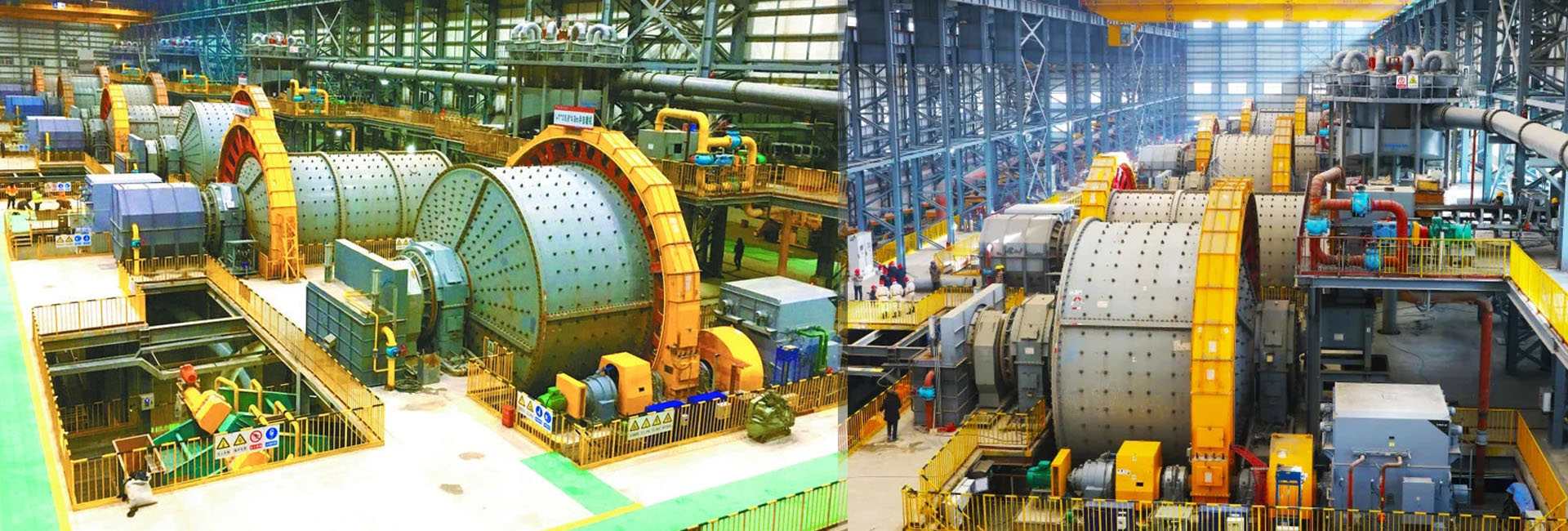

- Vibrating screens and filter press

- Hydrocyclone

- Crusher wear parts and backing compound

- Flocculant

Stack sizer screens

Stack sizer screens

The Stack Sizer screen redefines fine particle wet screening, offering high capacity and exceptional efficiency in minimal space. Consisting of up to 3-10 individual screen decks positioned one above the other and operating in parallel, the Stack Sizer provides a unique combination of high capacity and efficiency that sets the Stack Sizer far above the nearest competition.

Consult now

Details:

-

Specifications

- Size(W)

- 1045-1450 or customize

- Capacity ( t/h )

- 50-150

Water and undersize particles passing through the screen fall into an undersize collection pan, which empties into the common undersize collection launder that carries the material to the undersize discharge flange. Large particles are conveyed along the top of the screen panels to the end where they fall off into the oversize hopper. Oversize material is then discharged through the flanged port on the underside of the hopper.