- Polyurethane screens

- Polyurethane fine screen panels

- Polyurethane coated wire screens

- Dewatering screen panels

- Flip flow screen panels

- Rubber screens

- Woven wire screens

- Self cleaning screens

- Perforated plate screens

- Screening accessories

- Polyurethane sheets and lined pipes

- Polyurethane rollers and tires

- Rubber wear liners and rubber lined pipes

- Conveyor belts and conveyor pulley

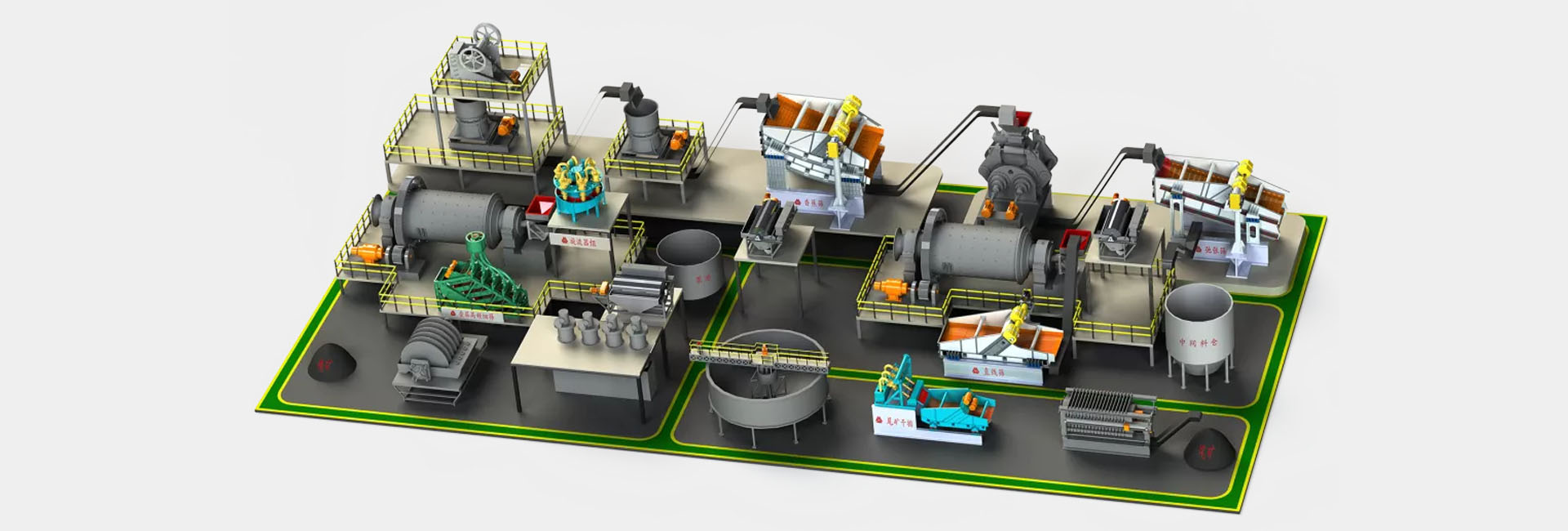

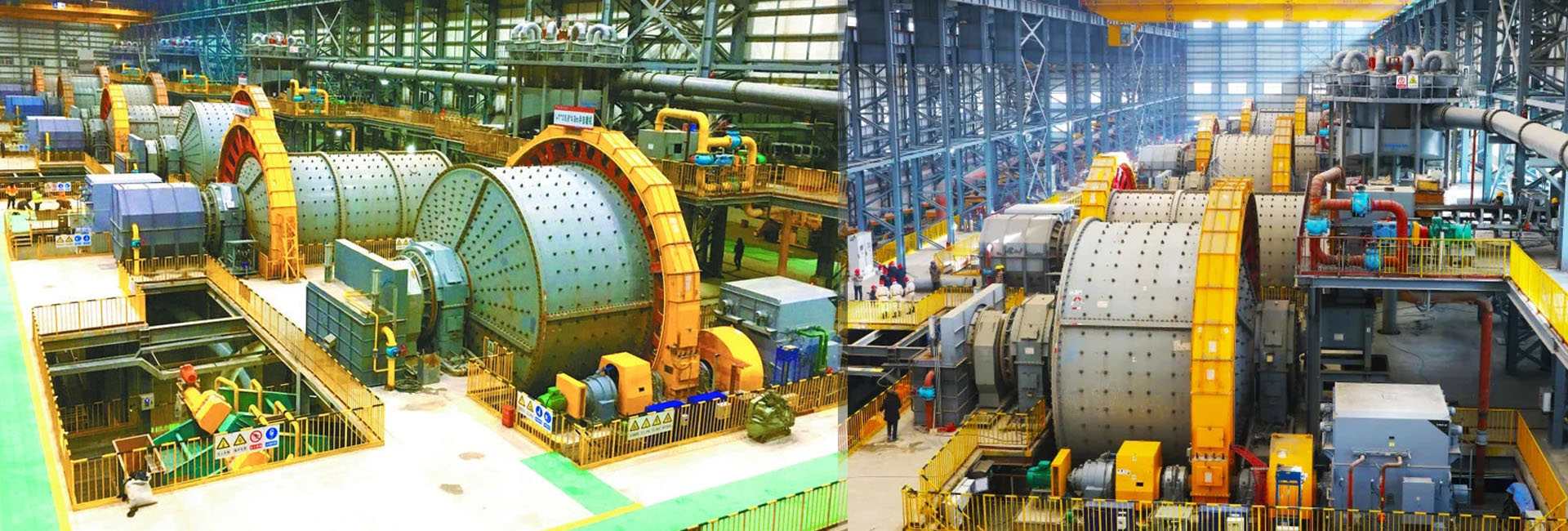

- Vibrating screens and filter press

- Hydrocyclone

- Crusher wear parts and backing compound

- Flocculant

Flocculant

Flocculant

Details:

Specifications

- Solid content (%)

- ≥88

- Molecular weight (million)

- 5-50

- Dissolving time (min)

- ≤60

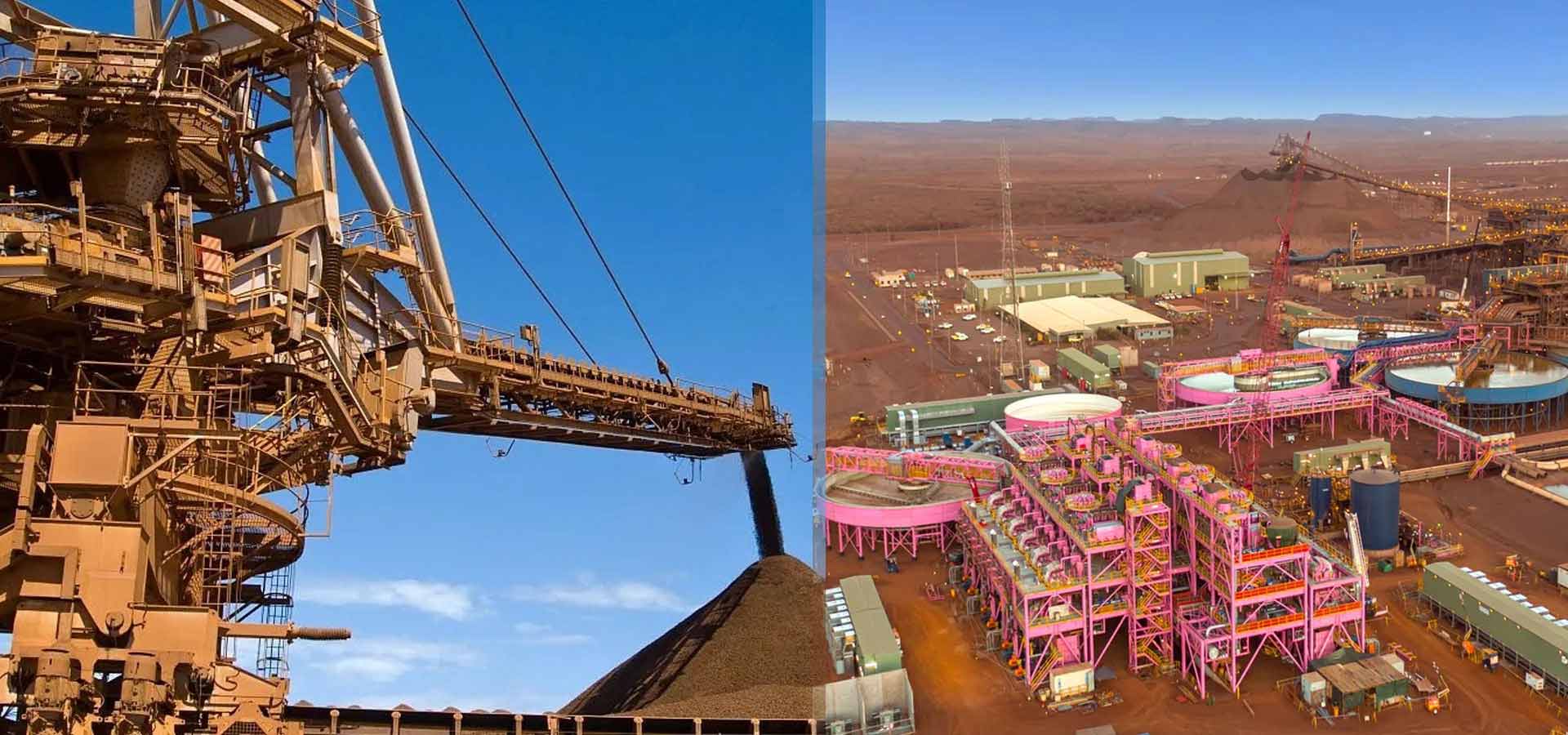

Seiko offers a range of products for customers in alumina, cooper, nickel, gold, iron ore, coal, phosphate, white pigments and aggregates. We understand your special needs for increased mineral recovery, the importance of water recycling and increased energy efficiency. Our full range of polymer products which includes non-ionic, anionic and cationic and zwitterionic products, all at varying molecular weights to suit the varied needs within the mining industry:

• Coal Washing

• Tailing Treatment

• Solid Liquid Separation by Filtration and Centrifugation

• Other Mineral Processing for Gold, Silver, Iron, Nickel, Cooper

Coal Washing

Along with the booming of infrastructure in all over the world, the coal industry began to expand which results to many operational challenges including fines handing and effluent management. The process of coal washing is essential to separate harmful metals from raw coal. Our portfolio flocculant and coagulants will make you operations more efficiency to get the clean coal.

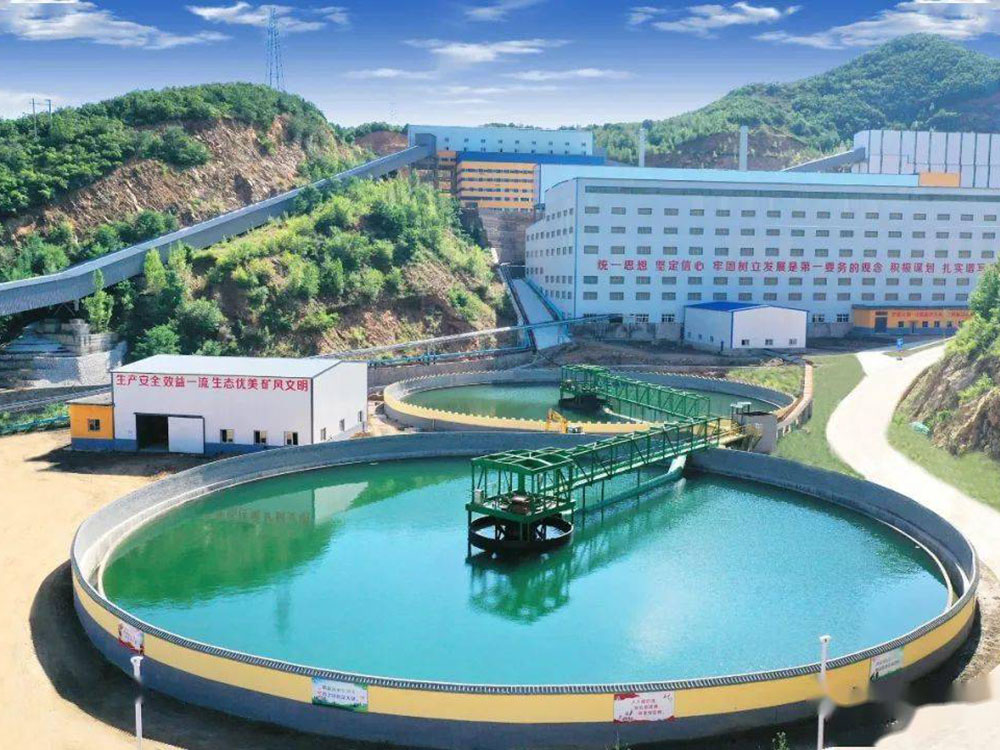

Tailing Treatment

A certain amount of mine dumps are produced as a waste during mining process which needs to be handled. The most common way of tailing treatment is to thicken the material prior to disposal and to get the water reuse in the process.Seiko flocculant could add to this thickening process to increase the setting rate the fine solids and reduce the size of the thickeners needed. The proper application of the flocculant could impact the whole operational efficiency. Seiko team could help you to choose the optimize products.

Solid Liquid Separation by Filtration and Centrifugation

Seiko full range of products is developed for the solid liquid separation in mining process to improve the performance of mineral processing and mine wastewater treatment systems. Seiko coagulants could increase the efficiency of flocculant used for solids removal in wastewater clarification, through neutralize surface charges. Seiko flocculant can aid sedimentation in water clarification, to be used together with a coagulant for charge neutralization.

Other Mineral Processing for Gold, Silver, Iron, Nickel, Cooper

Customized solutions could be designed by Seiko team about more separating mixtures to be used in foam control, flotation concentrate thickening, and tailing flocculation etc.